ASIC Miner ICERIVER KAS KS0 Profitability In the realm of cryptocurrency mining, the Iceriver KAS KS0 miner has garnered widespread attention. Tailored specifically for the Kaspa network's KHeavyHash algorithm, it boasts high hashing power and low power consumption, making it an ideal choice for many miners. In this article, we will comprehensively assess IceRiver KS0 profitability while considering the Kaspa market conditions and the attributes of KS0 miner. Kaspa Market Dynamics Kaspa is a vibrant cryptocurrency network aimed at delivering high performance and scalability for everyday transactions. At the time of writing this article, the Kaspa coin trades at approximately $0.04959. But it's essential to note that cryptocurrency markets are highly susceptible to price volatility. Hence, investors must remain vigilant about market dynamics. Additionally, the Kaspa network's mining difficulty and reward mechanisms play a role in mining returns. Attributes of the IceRiver KS...

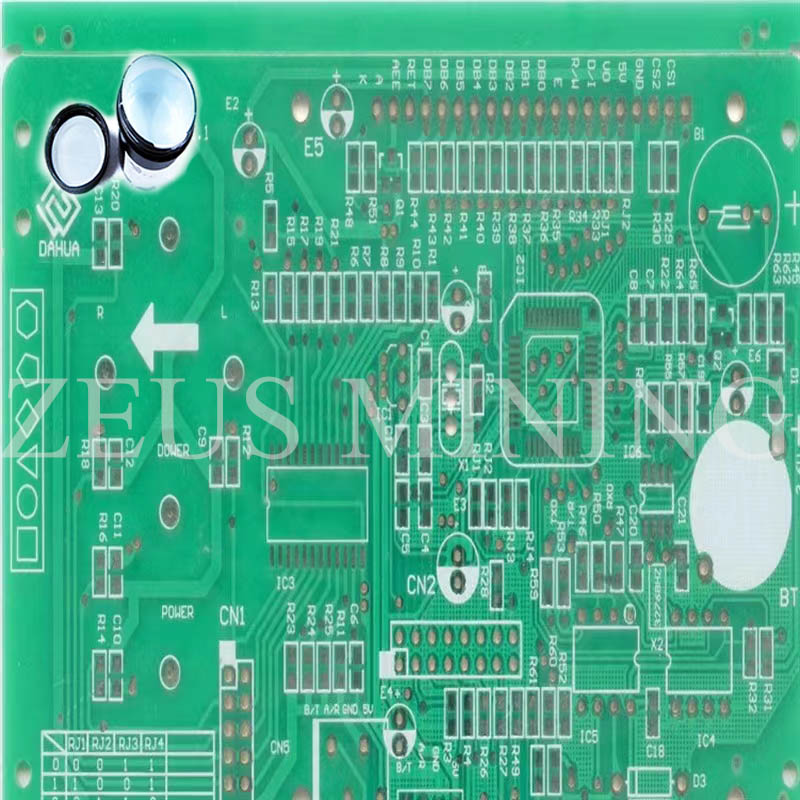

Types of PCB inks and precautions for use

PCB ink refers to the ink used for printed circuit boards, and its essential physical properties are the viscosity, thixotropy, and fineness of the ink. In the manufacturing process of printed circuit boards, it is necessary to use inks with suitable viscosity and proper thixotropy to improve the fidelity of PCB images. The so-called viscosity is the internal friction of the liquid, that is, the frictional force generated by the internal liquid when one layer of liquid slides on another layer of liquid under external force. In addition, the temperature has a specific effect on ink viscosity.

Thixotropy means that the viscosity of the liquid decreases under stirring and can quickly return to the original viscosity after standing for a while. To obtain high-quality screen printing results, the thixotropy of the ink is very important. It can speed up the speed of the ink through the mesh; once the scraper stops moving, the ink returns to a static state, and its viscosity will quickly return to the original required data.

Thixotropy means that the viscosity of the liquid decreases under stirring and can quickly return to the original viscosity after standing for a while. To obtain high-quality screen printing results, the thixotropy of the ink is very important. It can speed up the speed of the ink through the mesh; once the scraper stops moving, the ink returns to a static state, and its viscosity will quickly return to the original required data.

PCB inks are mainly divided into three categories:

It contains circuit inks, solder mask inks, and character inks.

Circuit inks act as a barrier to prevent line corrosion. It plays the role of protecting the circuit during the etching process. It is resistant to acid corrosion and alkali corrosion.

After the circuit is completed, apply solder mask ink on the circuit to protect the circuit well. The glue is neutral, acid and alkali resistant, non-corrosive to all materials (metals such as gold, copper-phosphorus, bronze, and other materials and silica gel, rubber, and other materials are not oxidized), no damage to components, no corrosion of parts, green and environmental protection. It can effectively help miners improve mining efficiency and prolong the service life of miner circuit boards.

Character inks are often used to mark circuit boards. Usually, it is white.

In addition to the three types of inks listed above, there are other inks, such as peelable adhesive inks, which protect parts that do not need to be treated during copper plating or surface treatment and can then be peeled off; silver paste inks, etc.

In addition to the three types of inks listed above, there are other inks, such as peelable adhesive inks, which protect parts that do not need to be treated during copper plating or surface treatment and can then be peeled off; silver paste inks, etc.

Notes on the use of ink:

1. In any case, the temperature of the ink must be kept below 20-25°C, and the temperature change should not be too significant. Otherwise, it will affect the viscosity of the ink, the quality and effect of screen printing, and it is recommended that you store it at room temperature.

When the ink is stored outdoors or at different temperatures, it must be left at ambient temperature for several days before it can be used again. Otherwise, the ink tank can reach the proper working temperature. This is because using cold ink can cause screen printing to fail, causing unnecessary trouble.

2. Before use, the ink must be thoroughly mixed. If air enters the ink accidentally, it is recommended to let it sit for a while before using it. If thinning is required, first mix well and then test for viscosity. Ink tanks must be sealed immediately after use. At the same time, never put the used ink back in the ink tank.

3. It is best to use a mutually compatible cleaning agent, and the cleaning agent should be comprehensive and clean. It is best to use it with a cleaning solvent when cleaning again.

4. After the ink is dried, it must be done in a device with a sound exhaust system.

5. To maintain the operating conditions, screen printing is carried out on the job site that meets the technical requirements.

The ink protects the copper foil during the production process so that the copper skin is not exposed and affects the subsequent process. Although there are photosensitive ink, carbon oil, and silver oil, both carbon oil and silver oil are conductive. The color classification can be divided into white oil, black oil, green oil, red oil, blue oil, and butter.

I will show you much about the precautions and functions of PCB ink use. I hope to provide you with some references!

When the ink is stored outdoors or at different temperatures, it must be left at ambient temperature for several days before it can be used again. Otherwise, the ink tank can reach the proper working temperature. This is because using cold ink can cause screen printing to fail, causing unnecessary trouble.

2. Before use, the ink must be thoroughly mixed. If air enters the ink accidentally, it is recommended to let it sit for a while before using it. If thinning is required, first mix well and then test for viscosity. Ink tanks must be sealed immediately after use. At the same time, never put the used ink back in the ink tank.

3. It is best to use a mutually compatible cleaning agent, and the cleaning agent should be comprehensive and clean. It is best to use it with a cleaning solvent when cleaning again.

4. After the ink is dried, it must be done in a device with a sound exhaust system.

5. To maintain the operating conditions, screen printing is carried out on the job site that meets the technical requirements.

The ink protects the copper foil during the production process so that the copper skin is not exposed and affects the subsequent process. Although there are photosensitive ink, carbon oil, and silver oil, both carbon oil and silver oil are conductive. The color classification can be divided into white oil, black oil, green oil, red oil, blue oil, and butter.

I will show you much about the precautions and functions of PCB ink use. I hope to provide you with some references!

Comments

Post a Comment

Tell us your opinion