How to use Antminer BM1387 tin tool to replace damaged chips?

In the repair work of the hash board, the most common problem is to replace the ASIC chip, which is the most easily damaged part of the hash board. In this article, I will use Antminer as an example to show my friends how to use Antminer BM1387 tin tools to replace damaged chips? Although there are many chip models, most of the pin positions and sizes are the same. ASIC chips are usually small in size and the pins are arranged closely, which brings great difficulty to maintenance and replacement. Because when replacing a new ASIC chip, it is necessary to accurately apply solder paste on each tiny pin, then heat it to melt, and finally fix it on the hash board.

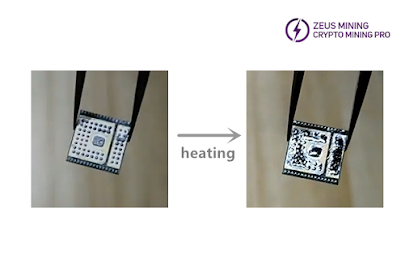

For how to solve this problem, after various attempts, we finally chose a convenient and efficient way: making professional tin tools (ASIC tin tools). Its principle is to fix the chip on the base, then use a special steel mesh to align the pins of the chip, and then apply the solder paste to the steel mesh. The solder paste will penetrate into the pins of the chip along the customized small holes of the steel mesh. Remove the stencil and heat the solder paste on the pins of the chip.

Method and principle of use:

1: Fix the ASIC chip on the base.

2: Place the ASIC tin tool steel plate on the base.

3: Pay attention to check whether the chip pin position is accurate.

4: Apply solder paste on the steel plate.

5: Take out the chip and heat it until the solder paste melts. After cooling, it can be installed on the hash board.

Feature description:

At first, people used aluminum alloy materials to make tin tools but later discovered that such materials are very easy to generate static electricity on the package shell of the chip, and it is easy to damage the ASIC chip during the replacement process. Therefore, after many repairers have replaced the new chip, the Hash board still cannot run. This is most likely because the new chip has been damaged. Therefore, after research, we adopted the most stable but relatively high-cost carbon compound as the material and re-developed a new tin tool, which has more wear resistance, high-temperature resistance, and anti-static characteristics.

If the custom stencil is offset, you can adjust it with the 6 screws on the front. In addition, you can also replace the custom stencil by removing these 6 screws.

Comments

Post a Comment

Tell us your opinion