ASIC Miner ICERIVER KAS KS0 Profitability In the realm of cryptocurrency mining, the Iceriver KAS KS0 miner has garnered widespread attention. Tailored specifically for the Kaspa network's KHeavyHash algorithm, it boasts high hashing power and low power consumption, making it an ideal choice for many miners. In this article, we will comprehensively assess IceRiver KS0 profitability while considering the Kaspa market conditions and the attributes of KS0 miner. Kaspa Market Dynamics Kaspa is a vibrant cryptocurrency network aimed at delivering high performance and scalability for everyday transactions. At the time of writing this article, the Kaspa coin trades at approximately $0.04959. But it's essential to note that cryptocurrency markets are highly susceptible to price volatility. Hence, investors must remain vigilant about market dynamics. Additionally, the Kaspa network's mining difficulty and reward mechanisms play a role in mining returns. Attributes of the IceRiver KS...

Antminer S17 T17 series hash board heat sink transformation tutorial

After long-term operation or transportation, the S17 and T17 series Antminers will risk the heat sink falling off. However, the falling heat sink will directly cause the ASIC to be damaged due to poor heat dissipation, resulting in a short circuit of the hash board or abnormal operation of the miner, thus causing irreparable losses.

However, if you reinstall the heat sink, it is highly likely to fall again. Therefore, it is recommended that you convert the ordinary S17 heat sink into an S17 upgraded heat sink to speed up the miners' heat dissipation and improve the miners' operation efficiency.

The primary purpose of this tutorial is to teach you how to replace a dropped normal heat sink with an upgraded heat sink.

Fault phenomenon:

The heat sink has come off.

Repair process:

1. First, place the air outlet of the desoldering gun vertically 6mm away from the heat sink, heat for about 12 seconds, and gently remove the heat sink;

2. To achieve a more uniform heat dissipation effect, we can use a professional tin grinding fixture to polish the ASIC;

3. After grinding, the screw base will be welded;

Note: The corresponding welding positions will differ for different heat sink models. Please weld according to the actual position of the screw holes of the heat sink.

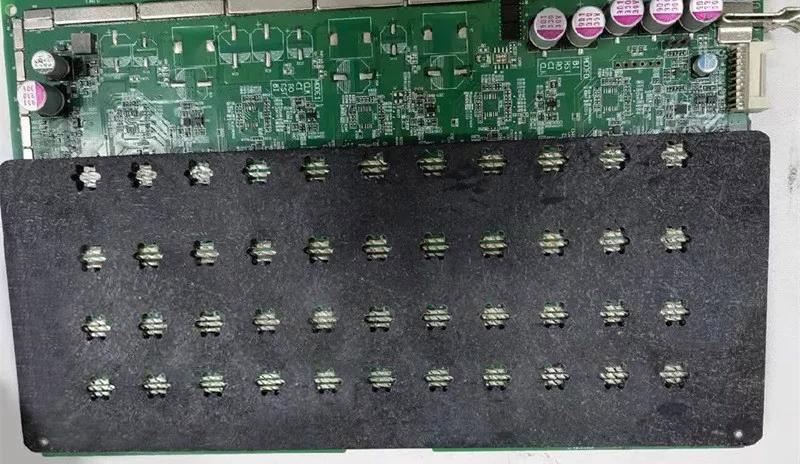

4. If the number of welding is too much, it can also be welded with a professional screw fixing mold;

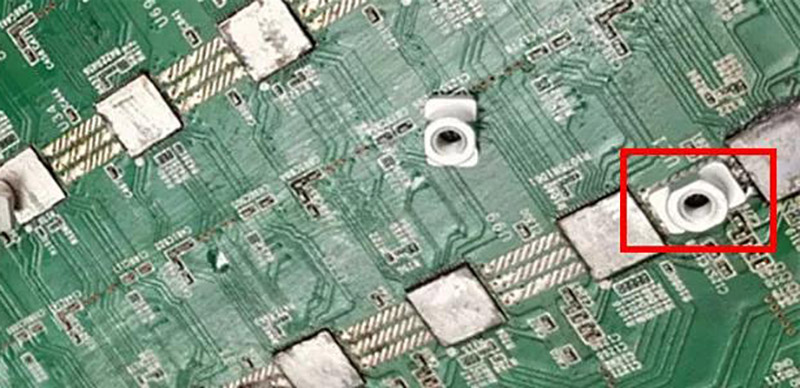

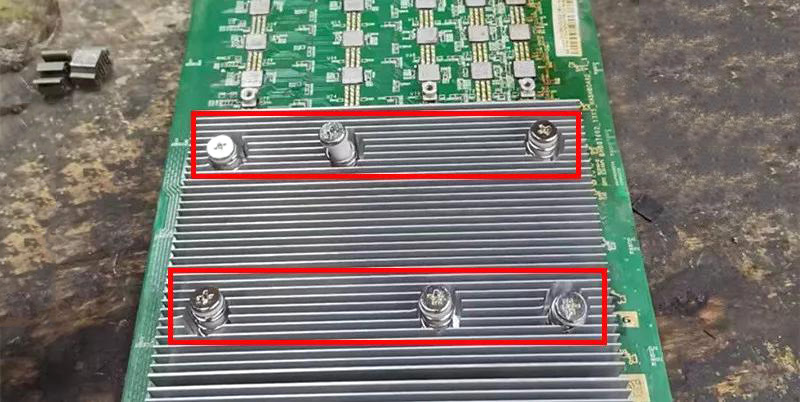

5. The effect diagram after the welding of the screw seat is completed;

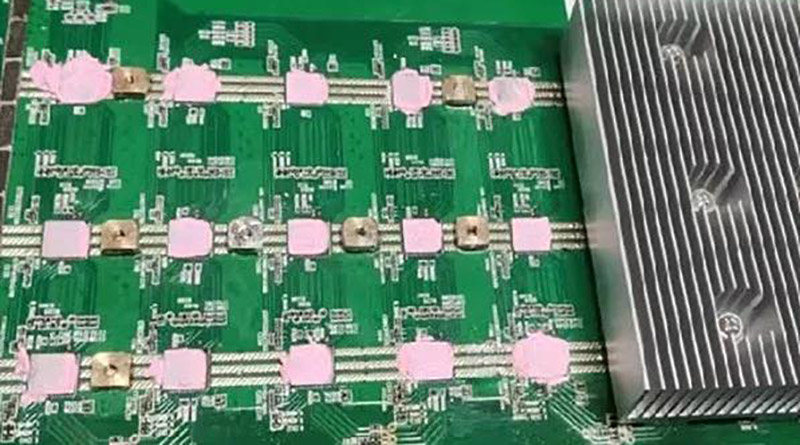

6. After the soldering is completed, apply the prepared thermosetting adhesive evenly on the back of the hash board ASIC chip;

7. Place the upgraded heat sink in the standard position and fix it with screws.

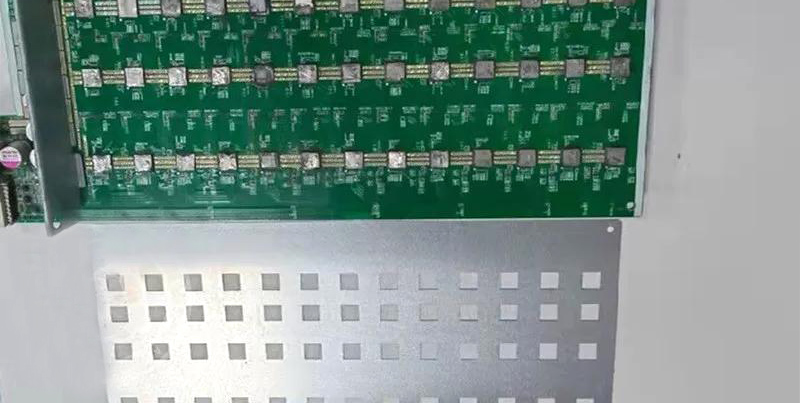

8. After the installation is completed, the finished product rendering is as follows:

Note: It is recommended that you use professional maintenance tools to improve efficiency and ensure the accuracy of maintenance.

Comments

Post a Comment

Tell us your opinion