ASIC Miner ICERIVER KAS KS0 Profitability In the realm of cryptocurrency mining, the Iceriver KAS KS0 miner has garnered widespread attention. Tailored specifically for the Kaspa network's KHeavyHash algorithm, it boasts high hashing power and low power consumption, making it an ideal choice for many miners. In this article, we will comprehensively assess IceRiver KS0 profitability while considering the Kaspa market conditions and the attributes of KS0 miner. Kaspa Market Dynamics Kaspa is a vibrant cryptocurrency network aimed at delivering high performance and scalability for everyday transactions. At the time of writing this article, the Kaspa coin trades at approximately $0.04959. But it's essential to note that cryptocurrency markets are highly susceptible to price volatility. Hence, investors must remain vigilant about market dynamics. Additionally, the Kaspa network's mining difficulty and reward mechanisms play a role in mining returns. Attributes of the IceRiver KS...

Precautions for maintenance of BGA components

BGA is a chip packaged by the BGA packaging process, mainly including PBGA, CBGA, CCGA, and TBGA. Generally, the bottom of the package is connected to the solder ball array as the I/O terminal. The typical pitches of these packages solder ball arrays are 1.0mm, 1.27mm, and 1.5mm. The common lead-tin components of the solder balls are mainly 63Sn/37Pb and 90Pb/10Sn. However, the diameter of the solder balls varies because there is currently no corresponding standard for this.

From the perspective of BGA assembly technology, BGA has more superior characteristics than QFP devices, which is mainly reflected in the fact that BGA devices have less stringent requirements for placement accuracy. Therefore, theoretically, during the solder reflow process, even if the offset of the solder ball relative to the pad is as much as 50%, the device position will be automatically corrected due to the surface tension of the solder. This situation has been experimentally proved to be quite obvious.

Secondly, BGA no longer has the problem of pin deformation of devices such as QFP, and BGA also has better coplanarity than QFP and other devices. Compared with QFP, its terminal pitch is much larger, which can significantly reduce the solder joint "bridging" caused by solder paste printing defects; in addition, BGA has good electrical and thermal properties, as well as high interconnection density. The main disadvantage of BGA is that it is difficult to detect and repair solder joints, and the reliability requirements of solder joints are relatively strict, which restricts the application of BGA devices in many fields.

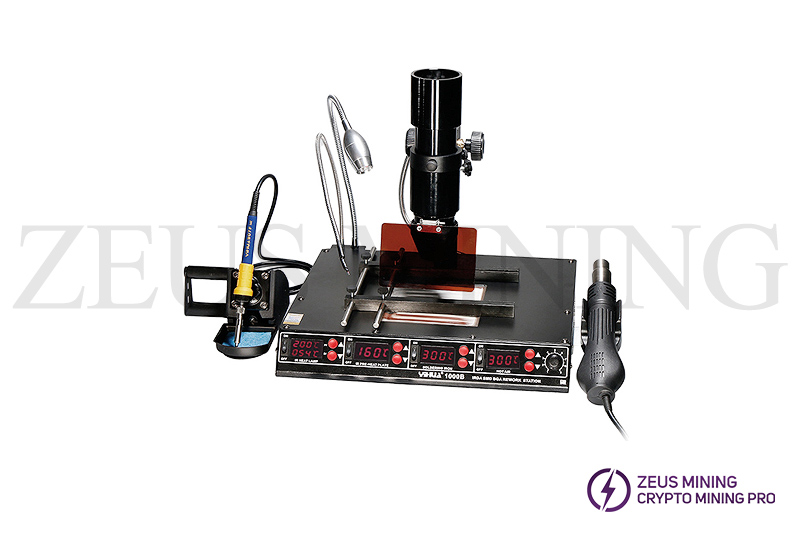

BGA soldering station

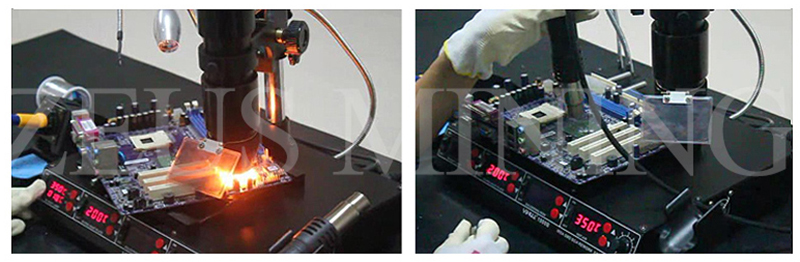

BGA soldering station is generally also called BGA rework station. It is special equipment used when BGA chips have welding problems or need to be replaced with new BGA chips. Due to the relatively high temperature requirements for BGA chip welding, heating tools (such as a portable desoldering gun) do not meet its needs.

The BGA soldering station follows a standard reflow soldering curve when it is working. Under normal circumstances, the success rate of BGA soldering station soldering can reach more than 98%.

Functional inspection of high-quality BGA soldering stations:

1. Whether there are 3 temperature zones

Including the upper heating head, the lower heating head, and the infrared preheating area. Three temperature zones are the standard configuration. Currently, most soldering stations on the market only have two temperature zones, including the upper heating head and the infrared preheating zone, resulting in a shallow welding success rate. Therefore, you must pay attention when purchasing.

2. Whether the lower heating head can move up and down

The lower heating head can move up and down, which is one of the necessary functions of the BGA rework station. Because when welding relatively large circuit boards, the air nozzle of the lower heating head, through structural design, plays a role of extra support. If it cannot move up and down, it cannot play the role of extra support, and the success rate of welding is significantly reduced.

3. Whether it has the function of intelligent curve setting

The temperature profile setting is one of the most important factors when applying a BGA rework station. If the temperature curve of the BGA rework station is not set correctly, the success rate of soldering is very low, and it cannot be soldered or disassembled.

4. Whether it has a welding function

If the temperature curve setting is not accurate, using this function can significantly improve the success rate of welding. The soldering temperature can be adjusted during the heating process.

5. Does it have a cooling function?

Cross-flow fans are generally used for cooling.

6. Is there a built-in vacuum pump?

It is convenient to absorb the BGA chip when disassembling the BGA chip.

7. It is not recommended to purchase a BGA rework station controlled by temperature instruments

There are many problems with BGA rework stations controlled by temperature gauges. The main problem is the high failure rate. This is because the temperature control of the BGA rework station is the core function, and the low-quality temperature control instruments cannot guarantee the temperature control accuracy and welding quality. In addition, the temperature meter data setting is cumbersome, and the operation interface is very unfriendly.

Excellent performance of BGA rework station

1. What is the temperature control accuracy of the BGA rework station?

Generally, the soldering temperature accuracy of reflow soldering is ±1°C, and the BGA rework station with temperature control accuracy greater than ±1°C is not recommended to buy. Due to the low temperature control accuracy, there is no way to achieve the precise temperature set by your temperature curve. Especially when small spacing is recommended for welding, it is straightforward to generate bridges.

2. Is the actual temperature curve displayed on the screen?

When the temperature curve is displayed on the screen, some manufacturers only display the set curve instead of the actual temperature curve, which means that their temperature control accuracy is very low.

BGA rework station equipment properties

1. The equipment must have safety protection functions, such as the failure of thermocouples, fans, and heating devices, no safety accidents can occur.

2. The material selection of the components of the equipment must be excellent, and the wiring must be standardized.

3. The equipment has a self-test function, which is convenient for users to locate faults.

4. The interface setting is reasonable, the operation is convenient, and the function buttons are easy to find.

Comments

Post a Comment

Tell us your opinion