ASIC Miner ICERIVER KAS KS0 Profitability In the realm of cryptocurrency mining, the Iceriver KAS KS0 miner has garnered widespread attention. Tailored specifically for the Kaspa network's KHeavyHash algorithm, it boasts high hashing power and low power consumption, making it an ideal choice for many miners. In this article, we will comprehensively assess IceRiver KS0 profitability while considering the Kaspa market conditions and the attributes of KS0 miner. Kaspa Market Dynamics Kaspa is a vibrant cryptocurrency network aimed at delivering high performance and scalability for everyday transactions. At the time of writing this article, the Kaspa coin trades at approximately $0.04959. But it's essential to note that cryptocurrency markets are highly susceptible to price volatility. Hence, investors must remain vigilant about market dynamics. Additionally, the Kaspa network's mining difficulty and reward mechanisms play a role in mining returns. Attributes of the IceRiver KS...

What are the commonly used adhesives in circuit boards?

In the repair and welding of circuit boards, we will use a variety of glues, but the following five are the most common; let's take a look!

1. Thermal grease

Thermal grease, also known as thermal paste, is a high thermal conductivity silicone insulating material. It can also be used for a long time at a temperature of -50 ~ +300 ℃ to maintain a grease state. Thermal grease has high thermal conductivity, excellent thermal conductivity, and a wide operating temperature. In addition, it is non-toxic, odorless, and non-corrosive, meets ROHS standards and relevant environmental protection requirements, and has stable chemical and physical properties.

The primary function of thermal grease:

Thermal grease is mainly used to fill the gap between the heating element and the heat sink to increase their contact area to achieve the best thermal conductivity. In addition, good use stability and good construction performance can effectively reduce the temperature of the miner's hash board so that the heat of the electronic components can be effectively dissipated and transmitted, ensuring the miner's smooth operation and service life.

The thermal grease is widely used in CPU graphics processors, notebook and desktop computers, high thermal conductivity modules, automotive headlight control, cooling devices, power conversion equipment, network communication equipment, electronic components, etc. It acts as a heat transfer medium and dramatically improves the heat dissipation effect.

2. Silicone glue

Because silicone glue is often used for bonding and sealing glass, it is commonly known as glass glue, and the glue should be sealed and stored. Silicone glue is a material that solidifies into a rigid, rubber-like solid when exposed to moisture in the air.

The primary function of silicone glue:

Silicone glue is widely used in electronic modules, sensors, electronic components, and other occasions where potting, insulation, and flame retardant are required, as well as the bonding of electronic components and the insulation between fixed components.

3. Hot melt adhesive

The hot melt adhesive strip is a solid adhesive made of ethylene-vinyl acetate polymer (EVA) as the primary material, adding modified rosin resin or petroleum resin and other ingredients. It is a plastic, non-toxic, tasteless, green and environmentally friendly adhesive. The physical state of the hot melt adhesive changes with the temperature within a specific temperature range, while the chemical properties remain unchanged. It does not contain water or solvent at all and has the characteristics of fast adhesion, high strength, aging resistance, non-toxicity, good thermal stability, and film toughness.

Heat the hot melt adhesive to the operating temperature, use a spray gun or coat it on the adherend, complete the bonding and shaping work within the glue's available time, clamp the adherend and cool it to room temperature. Hot melt adhesive is solid at moderate temperature, heated and melted into liquid, and cooled at room temperature to complete bonding within a few seconds, which can effectively fix electronic components and wire harnesses.

The primary function of hot melt adhesive:

Hot melt adhesive can be used for fixing electronic components, electronic bonding wiring, and bonding other electronic materials. It can even be used for mutual bonding, fixing handicrafts, packaging cartons, accessories, wood, textile samples, etc.

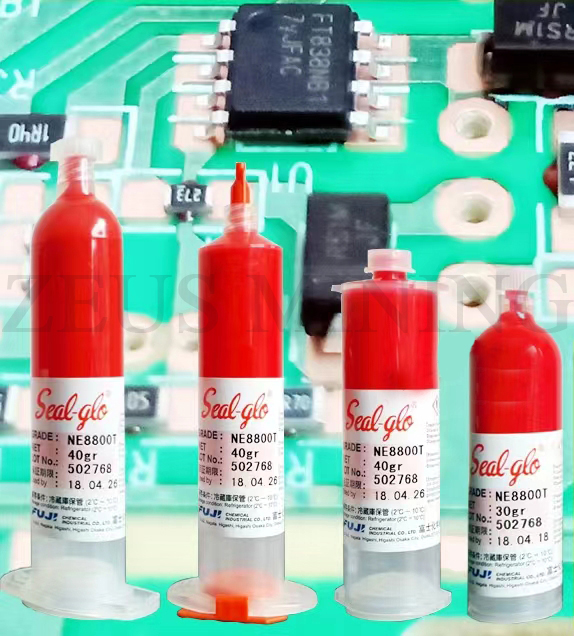

4. Red glue

Red glue is easy to cure after being heated. It is a polyolefin compound. When the temperature reaches 150 °C, the red glue changes from a paste to a solid. It is precise because of this characteristic of red glue that it is used to fix SMD components by dispensing or printing. The circuit board components can be heated and cured by oven or reflow soldering using SMD red glue.

Several characteristics of red glue:

① Stable adhesion of various chip components;

② It has viscosity and thixotropy suitable for screen printing, and the amount of glue is stable without brush leakage or tower edge;

③ It has good storage stability;

④ It has high adhesive strength, which can avoid the misalignment of components during high-speed placement.

The primary function of red glue:

Red glue is used to fix the SMD components of the circuit board, mainly for bonding, or used together with solder paste for reinforcement and fixation.

5. Yellow glue

Yellow glue has a pungent odor and is a soft self-bonding water-based adhesive with excellent insulation, moisture-proof, shock-proof, and thermal conductivity, enabling electronic components to operate safely under harsh conditions.

The curing speed of yellow glue is related to the change in ambient temperature: the higher the temperature, the lower the humidity, the greater the wind speed, the faster the curing speed, and vice versa. Therefore, when the coated parts are placed in the air, there will be a phenomenon of slow skin formation. Note that the operation should be completed before the surface is skinned.

The primary function of yellow gum:

Fixed inductors, coils, transformers, electrolytic capacitors, receiving heads, and other electronic products can protect and seal electronic components and be used for electrical components potting, moisture-proof circuit boards, etc.

Comments

Post a Comment

Tell us your opinion